The different types of manufactured concrete products and the process by which they are produced. The information presented here is built upon in more advanced topics covered in other programs by NCMA. This program is best suited for those with little to no background in concrete masonry systems or materials or for those desiring a refresher course in concrete masonry. This presentation covers a basic overview of concrete masonry systems and materials including how concrete masonry units are manufactured, masonry terminology, masonry mortars, masonry grouts, and construction practices and requirements. Understand how concrete masonry and hardscape products when combined with mortar, grout, reinforcing steel, or geosynthetics form a cohesive, strong structural assembly that can effectively resist the design loads. Understand that concrete masonry and hardscape products are noncombustible and that fire resistance rating of a masonry block assembly easily can be determined according to the amount of material and the aggregate type used in the manufacture of the unit. Recognize that all unit shapes are designed to obtain the most structural benefit.  Understand that through the use of extremely high pressure and vibration, very strong, durable and sustainable concrete masonry and hardscape products are made with low cement and low water content. Additionally because of the highly specialized process and equipment used in their manufacture, concrete masonry units are structurally sound and sustainable construction products. 2 R-values and U factors (thermal transmittance) do not take into account the effects of thermal mass, and by themselves are inadequate in describing the heat transfer properties of construction assemblies with significant amounts of thermal mass such as concrete masonry.Participants will learn first-hand through instruction and observing the manufacturing process how concrete masonry and hardscape units are made. R-value is expressed as the thickness of the material divided by the thermal conductivity. Thermal mass is not to be confused with R-value, also known as thermal resistance. Night, and then it is able to absorb heat again the next day. This delay in heat transfer is known as “damping.”Ĭoncrete Masonry Units mass is cooled by natural ventilation during the Concrete Masonry slowly releases heat into the interior spaces during late afternoon and evening when buildings are usually empty. When outdoor temperatures are at their peak, the inside of the building remains cool, because the heat has not yet penetrated the concrete masonry unit, producing a time lag as seen in Figure 1. The resulting energy savings increase with high swings in ambient temperature. Keep in mind concrete masonry units thermal mass flattens out daily temperature differentials and therefore reduces heating and cooling loads on the building’s HVAC system. Thermal mass tends to decrease both heating and coolingĬonstructed with masonry can require 18% – 70% less insulation than similarįrame buildings, while still providing an equivalent level of energy efficient Releasing heat as the interior and/or exterior temperature and radiantĬonditions fluctuate. Surface area) are capable of affecting building energy loads by storing and The effectiveness of thermal Mass is dependent uponĬlimate building design insulation position wall heat capacity. Type and location of insulation finish materials and grouted areas. R-Value of masonry walls areĭetermined by the following characteristics: size, type and density of CMU Resistance (R-Value) as well as its thermal mass. Thermal Performance of masonry depends on its thermal

Understand that through the use of extremely high pressure and vibration, very strong, durable and sustainable concrete masonry and hardscape products are made with low cement and low water content. Additionally because of the highly specialized process and equipment used in their manufacture, concrete masonry units are structurally sound and sustainable construction products. 2 R-values and U factors (thermal transmittance) do not take into account the effects of thermal mass, and by themselves are inadequate in describing the heat transfer properties of construction assemblies with significant amounts of thermal mass such as concrete masonry.Participants will learn first-hand through instruction and observing the manufacturing process how concrete masonry and hardscape units are made. R-value is expressed as the thickness of the material divided by the thermal conductivity. Thermal mass is not to be confused with R-value, also known as thermal resistance. Night, and then it is able to absorb heat again the next day. This delay in heat transfer is known as “damping.”Ĭoncrete Masonry Units mass is cooled by natural ventilation during the Concrete Masonry slowly releases heat into the interior spaces during late afternoon and evening when buildings are usually empty. When outdoor temperatures are at their peak, the inside of the building remains cool, because the heat has not yet penetrated the concrete masonry unit, producing a time lag as seen in Figure 1. The resulting energy savings increase with high swings in ambient temperature. Keep in mind concrete masonry units thermal mass flattens out daily temperature differentials and therefore reduces heating and cooling loads on the building’s HVAC system. Thermal mass tends to decrease both heating and coolingĬonstructed with masonry can require 18% – 70% less insulation than similarįrame buildings, while still providing an equivalent level of energy efficient Releasing heat as the interior and/or exterior temperature and radiantĬonditions fluctuate. Surface area) are capable of affecting building energy loads by storing and The effectiveness of thermal Mass is dependent uponĬlimate building design insulation position wall heat capacity. Type and location of insulation finish materials and grouted areas. R-Value of masonry walls areĭetermined by the following characteristics: size, type and density of CMU Resistance (R-Value) as well as its thermal mass. Thermal Performance of masonry depends on its thermal #Concrete masonry unit calculator code#

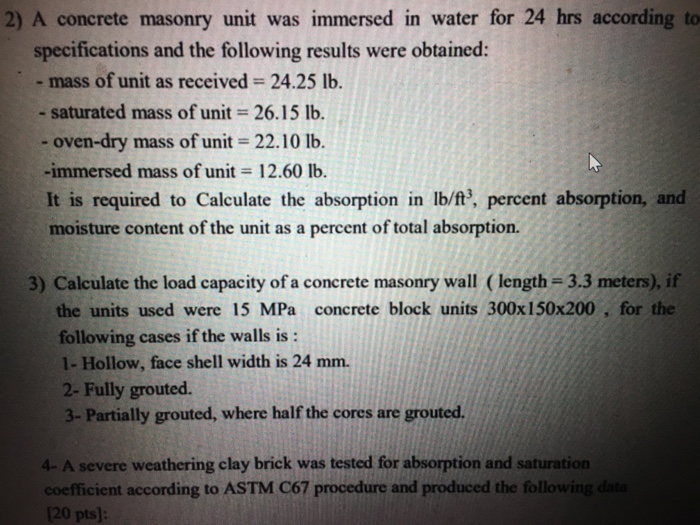

This wall systemĮxceeds current energy code in all 8 areas.

In addition to the thermal mass benefits, concrete masonryĬan provide continuous insulation with an R-Value of 14 or 20 (in this typicalĬavity wall) depending on the type of rigid insulation used. Insulation than frame wall systems to meet the energy requirements. To the thermal mass, the IECC permits concrete masonry walls to have less Temperature swings and shifts heating and cooling loads to off-peak hours. This reduction in heating and cooling loads moderates indoor Storage – remaining warm or cool long after the heat or air-conditioning has Importance of Thermal Mass in Energy EfficiencyĬoncrete masonry walls provide very effective thermal Understanding Masonry & Energy Efficiency With airtight walls,Ĭoncrete block also reduces wall leaks, which prevents energy loss andĬould lower your heating and cooling bills by 50 percent. Due to concrete masonry units thermal mass, a building constructed withĬoncrete block holds heat longer in cool weather, and cool air insideįor longer periods, even in the dead of summer.

0 kommentar(er)

0 kommentar(er)